What is cast iron?

Cast iron is an alloy between iron, carbon and silicon. Cast iron is poured at 1400degrees. Cast iron was invented back in 1700 and they were able to produce something like grey iron. They had no advanced processes for controlling the additives neither in in the sand nor in the iron. Temperature could only be adjusted by visual look.

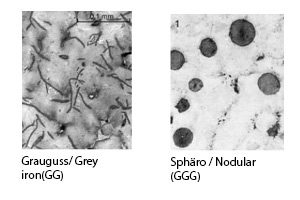

In Grey cast iron you will find the carbon as graphite flakes which gives a very brittle structure

In 1948 nodular cast iron was invented by adding magnesium and tight control of other elements and accurate timing, resulting the graphite to separate into spheroidal particles as the material solidifies. Magnesium most evaporates at 1100degrees.

Nodular cast iron today You find in many variants with different properties. Some with very good machine abilities and other for low temperature applications.

Both the grey and nodular cast iron are still being used widely in industry cookware and of course also automotive industry.

Why is cast iron relative corrosion resistant?

Some cast iron windows, fences and lamps are more than 100 years old and still in good shape, and some even without surface treatment. Stable windows survived despite whether outside and high degree of ammonia fumes inside, however we still can refurbish these windows.

The reason being is the high content of Carbon that blocks the oxygen to penetrate the surface. In the foundry language we call it the skin. Especially the skin has high degree of carbon and this is why You get grey hands when touching new raw cast iron. The skin helps to protect against the weather and some chemicals.

How to shape?

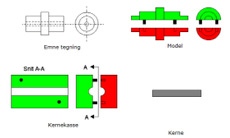

From a drawing we produce a 2-partet pattern. The pattern is being used to make imprints in the sand and therefore it needs to have sloped sides, which we call draft. If the part is hollow, we need to produce a core. The core is produced by sand with a kind of glue in a corebox.

The pattern and the corebox need to have approx. 1% oversize since the casting shrinks when its solidifying.

Nowadays we use smart 3D programs to create the shapes that the costumer need.

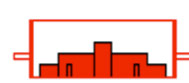

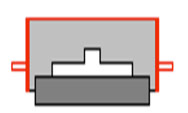

Pattern underpart is placed in a box

Filling with form sand

Stamping the sand

Pattern over part is placed in a box

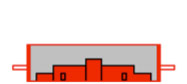

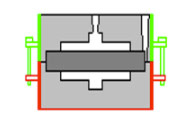

Cores are placed in the imprints in the model underpart

Modeloverpart is placed on top

Both patterns will be lifted out

Cores are placed in the imprints in the model underpart

Modeloverpart is placed on top

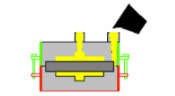

Liquid cast iron is poured in from a laddle at 1400degrees

Which glass to choose?

Cast iron windows are made by cast iron and originally fitted with 3-4mm single layer glassing. Cast iron has no isolating effects and only keeps out the cold wind. Today we have higher requirements for insulation.

A cast iron window can of course be equipped with energy glassing but You still “loose” some of the effect from the bars and the frame. The loss is difficult to quantify since its depending on the size of the bars and of course the total length.

If You need high degree of comfort You need to add a storm window. In protected buildings however it may be difficult to get the permission to install storm windows. In some cases, you need to use old timer glassing, which gives the authentic look.

The project/building owner should ask relevant authorities.

What type of bulb to choose?

First of all, you need to use energy saving bulbs. In our lamps we use E14 socket. Please check the datasheets for number af bulbs in the lampheads.

Effect, watt?

- Nowadays You should use either use 2 or 4 watt bulbs. The more ground that should be illuminated the higher no. of watt You should choose.

- Street lamps most often use the 4 watt bulbs.

- The smaller lamp heads uses then the 2 watt bulbs.

Color, kelvin?

LED bulbs are also available in different colors.

- 3000K is giving white illumination (High mounted lamps, Streetlamps, big squares or parks)

- 2700K is warm white. (small street, smaller parks and gardens)

- 2100K is an almost yellow light. It’s a cozier illumination and You will find much less dazzle effect.

- Below bulb Shows a Filament-bulb with a small E14 socket and 2200kelvin. The filament bulb looks like the old Edison carbon filaments.

U-values

When using storm windows, they should be mounted between 20 and 200mm behind the cast iron window. Around 100mm is normally very convenient. Below table shows the U-values from storm window alone.

In the right part, you find the total U-value including the contribution of still air between the cast iron window and storm window.

| Storm window alone | Cast iron window and storm window | ||

| dimensions | U-values | Dimension | U-values |

| 4mm one-layer glassing | 5,8 | 4mm glazing in cast iron window + 100mm air + 4mm one-layer glazing in storm window | 1,8 |

| 3-6-4 | 2,02 | 4mm glazing in cast iron window + 100mm air + 3-6-4mm energy glazing in storm window | 1,43 |

| 3-6-4 | 2,02 | 4mm energy glazing in cast iron window + 100mm air + 3-6-4mm energy glazing in storm window | 1,04 |

| 3-8-4 | 1,68 | 4mm glazing in cast iron window + 100mm air + 3-8-4mm energy glazing in storm window | 1,25 |

| 3-12-4 | 1,28 | 4mm glazing in cast iron window + 100mm air + 3-12-4mm energy glazing in storm window | 1,01 |

| 3-15-4 | 1,12 | 4mm glazing in cast iron window + 100mm air + 3-15-4mm energy glazing in storm window | 0,89 |